Friday, July 21, 2006

Frame

This is the frame I brazed together a few weeks ago. It just needs a little more tubing added for the Y axis motor supports and then it should be about good to go. Hopefully I'll get the tubing today, but may not have any time to do anything useful -- real work and all that.

I see there was a nice idea on the main blog yesterday which was to use compressed air to drive the piston instead of a motor. It should be able to get much better pressure. It should also fit fairly easily onto the same general scheme for my extruder without throwing it all out, so if my motor doesn't have enough oomph, I can switch to that.

I'll also be using preformed cylinders of CAPA as feedstock (so there are no bubbles). They should fit fairly snugly into the heater tube and possibly taper very slightly towards the top, so that as they are compressed or melt down any air that wants to escape around the outside can do so.

For the RepStrap I hope to get away with a slightly less fine extrusion size than a general purpose final RepRap. That may reduce the pressure requirements a little for my purposes and may allow extrusion with the little motors.

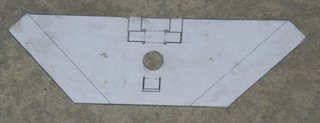

This is how I produced the brackets. Just print out the pattern (from PDF file), and cut it out with some snips. Here's one that's just started:

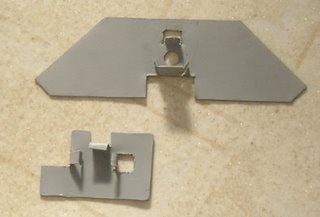

And here's the final result. They're pretty rough because I'm not too concerned about how pretty it is. They fit the bearings very snugly though and seem perfectly functional. The bearings just slot into place.

Some final bending of the corner brackets (the mounting flange) will be needed after they are in place to make it fit as closely as possible.